DC Motor –deliver high-power, reliable performance for heavy industrial applications like mills, hoists, and extrusion.

Product Category

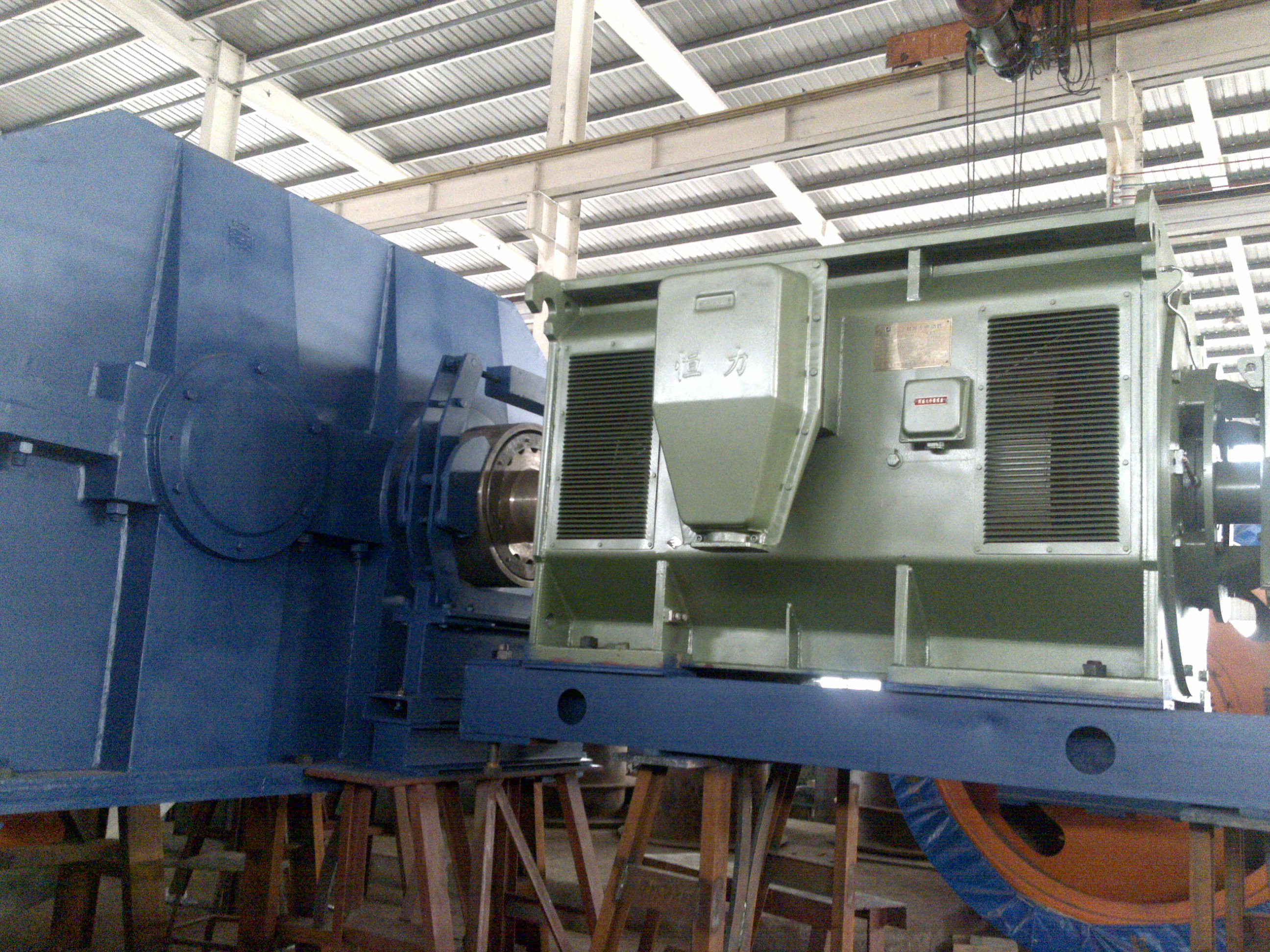

Hengli DC Motors, including Large Size Z, ZFQZ, and Z4 series, are widely used as prime movers in industries like metallurgy, metal cutting, paper-making, textile, cement, and plastic extrusion. These newly developed motors deliver reliable performance in mill auxiliaries, hoisting systems, cranes, and more. Hengli DC Motors, with over 68 years of expertise, focuses on customer-driven product development and custom solutions.

Application

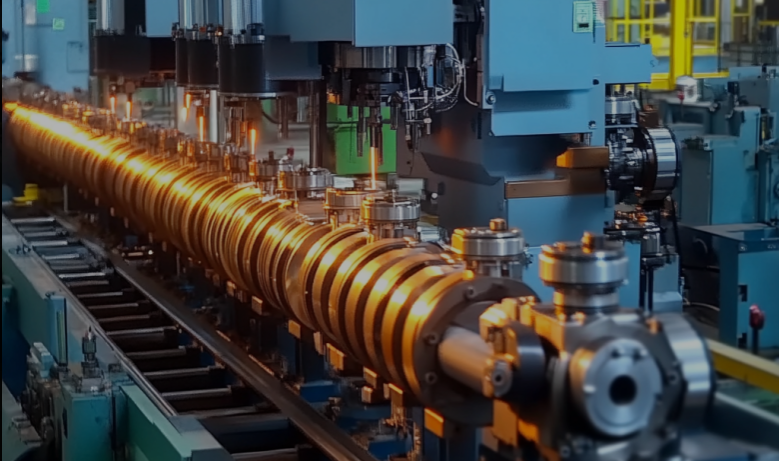

Metallurgy and Rolling Mills

Widely used in rolling mills, shear drives, and auxiliary systems, offering high torque and overload resistance in demanding industrial environments.

Machine Tools and Precision Equipment

Ideal for metal cutting, printing, and textile machinery, delivering stable speed control and reliable torque for high-precision operations.

Paper, Packaging, and Printing Industries

Ensures continuous operation and smooth performance in paper processing, packaging lines, and large-scale printing systems.

Cement, Plastic, and Rubber Processing

Drives mixers, rotary kilns, and extruders with durability and adaptability in harsh, high-dust conditions.

Heavy Machinery and Mine Hoisting

Perfect for hoists, mixers, and other heavy industrial equipment requiring high power, overload capacity, and stable control.

Product Advantages

DC Motors are suitable for a variety of heavy-duty industrial applications, providing reliable power and efficient performance.

High Overload Capacity

Hengli DC Motors can handle significant overloads, up to 250% for short durations, ensuring reliable operation in demanding industrial environments.

Durable and Long-lasting

Built for heavy-duty industrial use, these motors offer excellent durability and long service life, even in harsh conditions like high temperatures and dust.

Customizable to Specific Needs

These motors are available in various power ratings, frame sizes, and voltage options, making them highly adaptable to different industrial applications.

Efficient and Energy-saving

Designed for optimal energy efficiency, Hengli DC Motors help reduce operating costs and improve long-term sustainability in industrial settings.

FAQs

Q: What are the common applications of DC motors?

A: DC motors are commonly used in industries such as metallurgy, paper-making, textile manufacturing, plastic extrusion, and cement production, among others. They are ideal for driving heavy machinery like rolling mills, mixers, and hoists.

Q: What is the power range of Hengli DC motors?

A: Hengli DC motors range from 1.0kW to 2800kW, catering to various industrial requirements.

Q: What are the protection ratings of Hengli DC motors?

A: Hengli DC motors are available with protection ratings such as IP21S, IP23, IP44, and IP54, ensuring they can withstand different environmental conditions, including moisture and dust.

Q: Can the motor be customized based on my requirements?

A: Yes, Hengli DC motors can be customized to meet specific customer needs, including field voltage, armature voltage, insulation class, and encoder requirements.

Q: What is the maximum overload capacity of Hengli DC motors?

A: Hengli DC motors have a high overload capacity, with some models supporting continuous overloads up to 125%, 200% for short periods, and up to 250% for very brief durations, making them ideal for tough industrial applications.

Related Blogs

-

Linear induction motors evolved from rotary motors. When a three-phase (or polyphase) winding on the primary side is passed through a symmetrical sinusoidal alternating current, an air-gap magnetic field is created. When the longitudinal edge effect caused by the fracture at both ends of the iron co

Linear induction motors evolved from rotary motors. When a three-phase (or polyphase) winding on the primary side is passed through a symmetrical sinusoidal alternating current, an air-gap magnetic field is created. When the longitudinal edge effect caused by the fracture at both ends of the iron co -

DC motor controller is a special type of electrical equipment that converts electrical energy into mechanical energy. DC motor receives electrical energy by utilizing direct current, and then converts this energy into the automatic rotation of the motor. DC motors are almost ubiquitous, they utilize the magnetic field created by the currents that drive the rotor fixed to the output shaft, and the speed and output torque depend on the motor's design and electrical input.

DC motor controller is a special type of electrical equipment that converts electrical energy into mechanical energy. DC motor receives electrical energy by utilizing direct current, and then converts this energy into the automatic rotation of the motor. DC motors are almost ubiquitous, they utilize the magnetic field created by the currents that drive the rotor fixed to the output shaft, and the speed and output torque depend on the motor's design and electrical input.

Contact Us

If you have any inquiries or needs regarding DC Motor, don’t hesitate to reach out to our customer service team. Our experienced team is ready to provide you with comprehensive product details and assist you with any questions you may have.

Mob

+86-13486123098